Rod Pump Spacing Calculator

To calculate rod pump spacing, the Rod Pump Spacing Calculator uses a formula that incorporates fluid load and stroke number. This ensures accurate spacing, optimizing the pump’s performance and efficiency.

To calculate rod pump spacing, the Rod Pump Spacing Calculator uses a formula that incorporates fluid load and stroke number. This ensures accurate spacing, optimizing the pump’s performance and efficiency.

The Rod Pump Spacing Calculator is an indispensable tool for oilfield operators and engineers. It simplifies the process of determining optimal spacing in rod pumps, ensuring efficient fluid extraction and equipment longevity. Whether you’re working on well optimization or pump design, this calculator ensures accuracy and effectiveness, reducing operational inefficiencies and potential downtime.

RPS = (9 ∗ FL) / 1000 + (2 ∗ SND) / 1000

| Variable | Description | Unit |

|---|---|---|

| RPS | Rod Pump Spacing | Inches |

| FL | Fluid Load | Pounds |

| SND | Stroke Number | Cycles Per Day |

Example 1: Determine the rod pump spacing for:

| Step | Calculation | Result |

|---|---|---|

| Calculate FL term | (9 ∗ 800) / 1000 | 7.2 inches |

| Calculate SND term | (2 ∗ 10) / 1000 | 0.02 inches |

| Add terms | 7.2 + 0.02 | 7.22 inches |

The rod pump spacing is 7.22 inches.

Example 2: Find the spacing for:

| Step | Calculation | Result |

|---|---|---|

| Calculate FL term | (9 ∗ 1200) / 1000 | 10.8 inches |

| Calculate SND term | (2 ∗ 15) / 1000 | 0.03 inches |

| Add terms | 10.8 + 0.03 | 10.83 inches |

The rod pump spacing is 10.83 inches.

The Rod Pump Spacing Calculator is a specialized tool used to determine the appropriate spacing for rod pumps in oil wells. This calculator ensures optimal efficiency, reliability, and performance by accurately calculating the spacing requirements between the pump and the rod components.

By using this tool, operators can prevent issues like rod wear, inefficient pumping, or uneven load distribution.

With inputs like pump dimensions, rod length, and operating parameters, the calculator provides precise spacing values in units like inches or millimeters.

It’s a critical resource for achieving the desired pump efficiency, ensuring that the rod guide spacing is correct, and maintaining the integrity of the pumping system.

Additionally, this tool is compatible with formats like PDF, Excel, and online calculators, making it accessible and easy to use for engineers and technicians.

This calculator also integrates pump affinity laws, helping to assess overall pump performance and size the rod pump appropriately for the application.

Final Words:

In summary, the Rod Pump Spacing Calculator is a valuable asset for the oil and gas industry, ensuring precise spacing and enhanced performance of rod pump systems. Its reliability and versatility make it indispensable for optimizing well operations.

To estimate the weight of a pumpkin, multiply the square of its diameter by its height and a constant value of 0.7854. The Pumpkin Weight Calculator is a handy tool for estimating the weight of pumpkins based on their dimensions. This calculator provides accurate estimates when you’re planning a pumpkin-growing competition, determining transport logistics, or…

11 / 100 SEO Score First, measure the length, width, and desired sand depth of your aquarium. Multiply these values, then divide by the volume of sand per unit to find the total amount of sand needed in kilograms or pounds. An aquarium sand calculator is a tool used to calculate how much sand is…

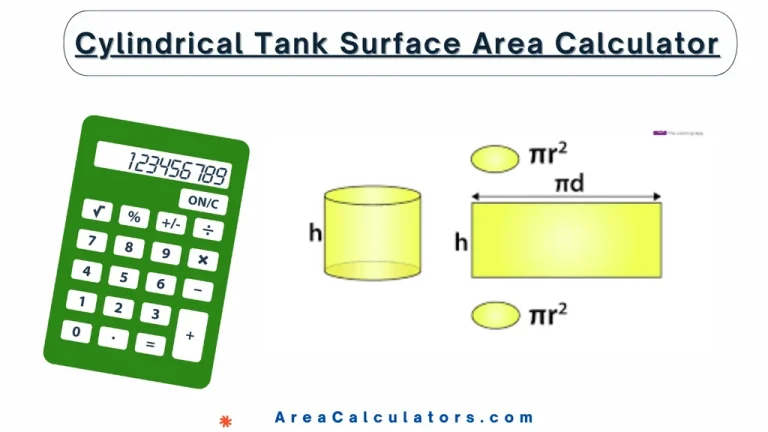

14 / 100 SEO Score To calculate the surface area of a cylindrical tank, add the radius of the base to the height of the tank, multiply that by the radius again, and then multiply the result by 2π. Cylindrical Tank Surface Area Calculator Base Radius (r): Height (h): Calculate Reset The Cylindrical Tank Surface…

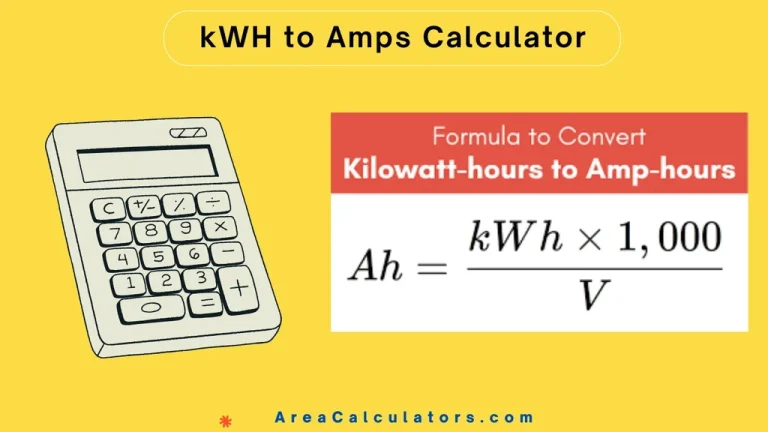

To convert kilowatt-hours (kWh) to amps, divide kWh by the voltage (V), multiply by 1000, and you’ll get the current in amps. The kWh to Amps Calculator provides a convenient way to convert energy usage in kilowatt-hours to the equivalent current in amps. This conversion is useful for evaluating power requirements and understanding electrical consumption…

To convert barbell weight to an approximate dumbbell weight, subtract 20% from the barbell weight. The Barbell to Dumbbell Weight Conversion Calculator supports lifters and fitness enthusiasts to find equivalent weights when switching between barbell and dumbbell exercises. This tool is of vital importance for them. Because, it facilitates them in adjusting weight loads for…

To find the date 50 days ago, simply subtract 50 days from today’s date. 50 Days Ago Calculator Enter today’s date to calculate the date 50 days ago Today’s Date Date 50 Days Ago Calculate Reset The 50 Days Ago Calculator is a simple tool that helps you calculate the date exactly 50 days prior…